Laser Cleaning System

Laser Cleaning Overview

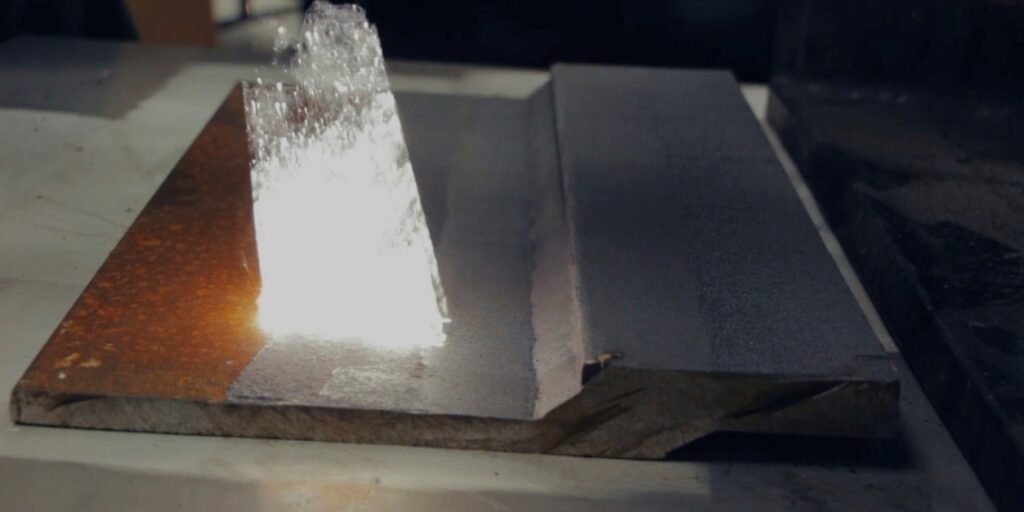

Laser cleaning is a revolutionary new technology that uses a focused beam of light to remove dirt, rust, and other contaminants from a wide range of surfaces. Laser cleaning is a non-contact, which means they do not physically touch the surface being cleaned, reducing the risk of damage or wear. Lasers are also eco-friendly, using no chemicals or abrasives, making them a smart choice for industrial and commercial applications such as automotive, electronics, and medical device manufacturing. Our laser cleaning services are highly efficient and versatile. Lasers can be used on metal, plastic, glass, and ceramics, quickly and efficiently removing contaminants, without all the cleanup and containment involved with traditional cleaning methods.

Top Benefits of Laser Cleaning

- High precision: Laser cleaning can remove dirt, rust, and other contaminants with high accuracy and minimal damage to the underlying surface.

- Non-contact cleaning: Laser cleaning uses a focused beam of light to remove contaminants, eliminating the need for physical contact and reducing the risk of damage to the cleaned surface.

- Eco-friendly: Laser cleaning machines do not use chemicals or abrasives, making them an eco-friendly alternative to traditional cleaning methods.

- Versatile: Laser cleaning can be used on many surfaces, including metal, plastic, glass, stone, wood, and ceramics.

- Time-saving: Laser cleaning can quickly and efficiently remove contaminants, saving time and labor compared to traditional cleaning methods.